technology

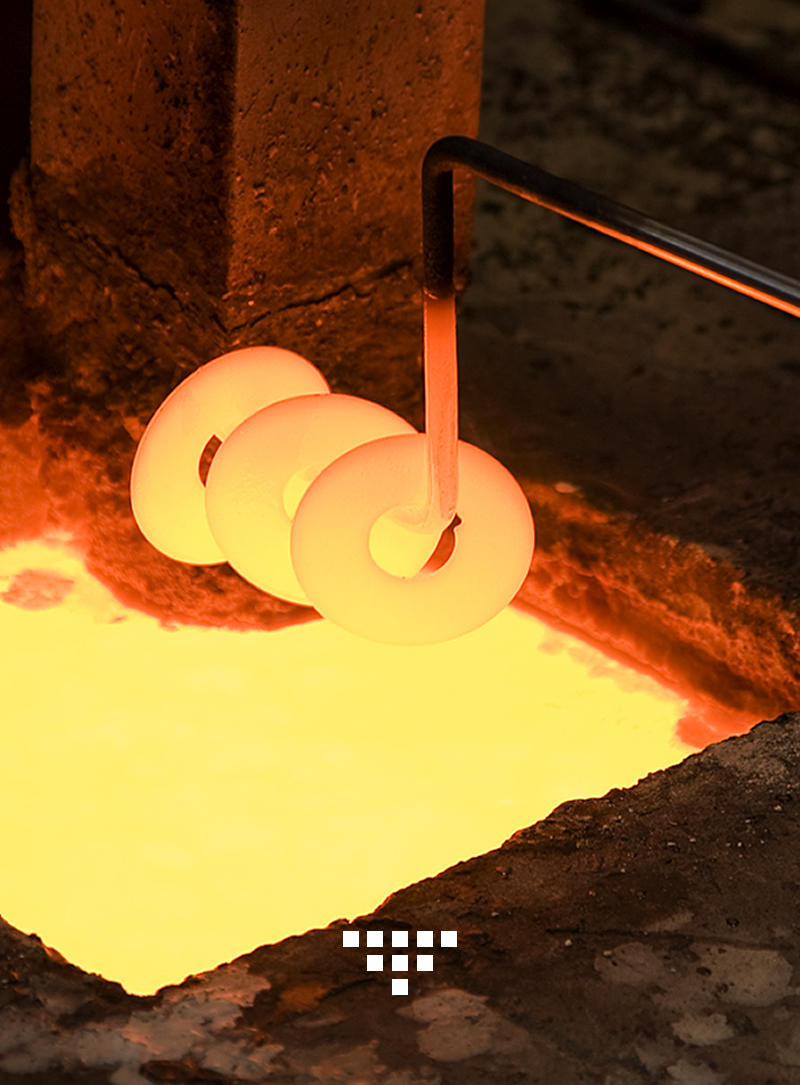

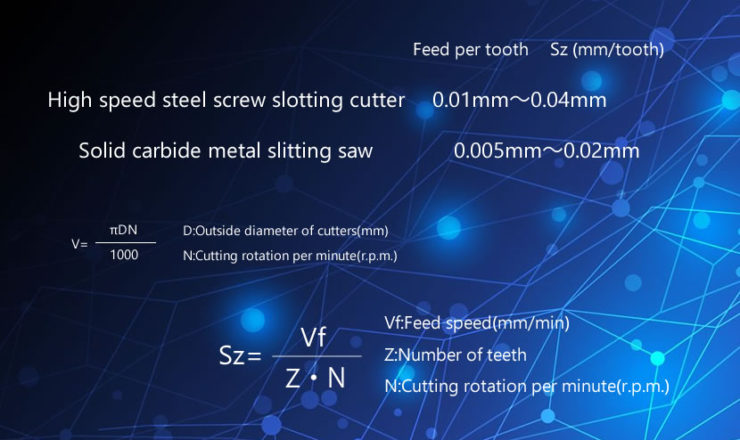

Breathe life into metal saws for our customer. The technology section is responsible for the design and production management of metal saws and other products. We discuss with our sales staff how to add special processing to the products according to customer needs and then create a design and pass it on to the manufacturing section. Special processing can include the addition of...